C. THE FCAS'S POLITICAL AND INDUSTRIAL STAGES

The decision to launch the FCAS programme was initiated by the CFADS resolution of 13 July 2017 in which France and Germany agreed to develop a European air combat system, reflected in the signature of the HLCORD signature already discussed and by the announcement of the Dassault/Airbus agreement in principle in April 2018 at the ILA trade show (Berlin's international air show). It was announced that France would be the programme's national leader and Dassault the international leader in return for German leadership of the European MALE drone and the future combat tank (MGCS).

1. The joint concept study

France and Germany awarded Dassault Aviation and Airbus the joint concept study (JCS) for €65 million on 6 February 2019.

Conducting such a joint concept study is a departure from the usual weapons programme philosophy. The JCS will clarify the HLCORD by analysing the various operational levels and translate them broadly into technological specifications (aircraft dimensions, number of decoy or saturation drones, the bandwidth needed for data transfer, etc.), i.e. the preferred basic concepts for the next generation combat aircraft, the drones, a system of systems and the related next-generation services. It also seeks to identify shared technological needs and demonstrators.

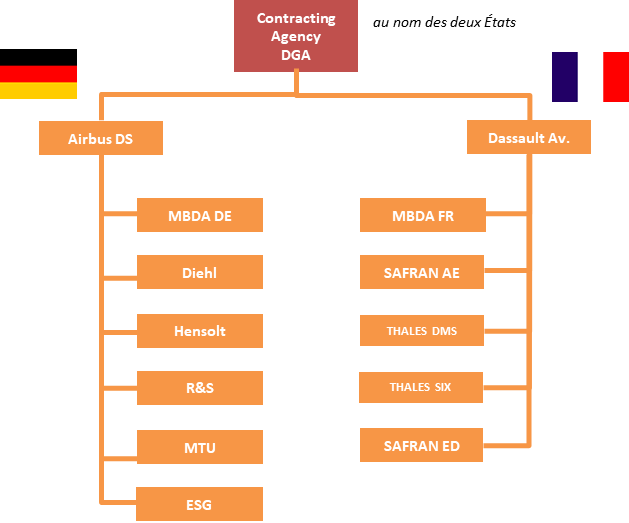

The JCS is entrusted to two teams under the control of the DGA acting on behalf of the two countries, a French team led by Dassault that includes MBDA France, Safran Aircraft engines and Safran Electronics and Defence, Thales DMS and Thales SIX, and a German team led by Airbus DS with MBDA Germany, Diehl, Hensolt, R&S, MTU and ESG.

The JCS will continue until the first half of 2021. Interim results on about ten architectures are expected in summer 2020, and the most promising target architectures will be selected in October and then fine-tuned until the study ends. Finally, they will be recalibrated according to the result of the demonstrations until production starts.

Diagram source: MBDA

2. Organisation in pillars, phase 1A of the demonstrator

a) Why one or several demonstrator(s)?

Creating one or several demonstrators is now planned (a demonstrator of the future combat aircraft, a demonstrator of the engine on the ground and, possibly, a later fighter drone demonstrator) for 2025 (or 2026 given the delay due to the length of Franco-German negotiations in 2019).

Making a demonstrator is not self-evident. Traditionally, weapons programmes go through a prototyping sequence which occurs at the end of the process. Prototypes are used to make the final adjustments, but these are devices that are nearly identical to the ones that will be produced. Demonstrators, on the other hand, arrive much earlier in the process, and these are not nearly finished products. Rather, they represent the definitive device in an incomplete way (the scale is not necessarily 1:1 nor built with the same materials as the definitive device) and highlight poorly understood aspects that need to be explored to avoid errors, for example, in aerodynamics or communication systems. It is also an intermediate step, an approval step that can be used to reorient development in the right direction to reduce the very significant gap between today's technologies and the very advanced technologies that will ultimately be implemented . The FCAS's demonstrator will help to combine the Rafale's handling and the Neuron's stealth in a single combat aircraft.

According to the programme directors that the mission heard, the same level of confidence in the technologies cannot be reached by computer simulation alone. Only a demonstrator can remove risk from the project by testing the technologies for a reasonable cost, while errors can be very costly if they are only discovered when the product is finalised , both for the manufacturers themselves who have committed themselves to specifications they cannot fulfil and for the governments who see the programme go out of control. Once again, the errors of the A400M are often held up as an example, but we could also discuss the F35, for example, which is now encountering problems with its stealth coating at supersonic speeds. 16 ( * )

b) A delay of a few months due to difficulties in the Franco-German negotiations

At the Paris Air Show in June 2019, the French president and German, French and Spanish defence ministers attended the presentation ceremony for a model of an NGF concept of 18 metres long (1:1 scale) at the Dassault Aviation stand. Two remote carriers, one manufactured by Airbus and the other by MBDA, were also shown at the event. At the end of the ceremony, several government and industrial framework agreements were signed . Defence ministers from the three countries signed a framework agreement that definitively formalised Spain's participation. Meanwhile, Dassault Aviation and Airbus signed an industrial agreement and filed a joint industrial offer with the DGA for the FCAS's initial demonstration phase (phase 1A), planned for 2020-2021.

The demonstrator's development contract could not be awarded at the Air Show due to difficulties between Safran and MTU around the industrial organisation for producing the NGF's engine (see below). The organisation decided at the government level (with Safran as prime contractor and MTU as main partner) was called into question by German stakeholders who contested the French engine manufacturer's leadership because it would penalise German industry. However, difficult negotiations resulted in a new agreement in early 2020 with the creation of a new joint venture between Safran and MTU.

An additional challenge came from the link established by Bundestag MPs between the FCAS and the MGCS (see box below). These MPs felt that the place reserved for German industry in the latter project could be improved.

The difficult negotiations on the industrial organisation of the future tank MGCS (Main Ground Combat System)

On land, France and Germany have been working since 2012 on a shared vision of their needs to replace combat tanks (the Main Ground Combat System - MGCS project) to replace the Leclerc and Leopard tanks. The letter of intent signed on 19 June 2018 during the ministerial seminar at Meseberg confirmed the shared desire to begin preparing a new phase of cooperation under German leadership to prepare a demonstrator of the future MGCS in 2024 which should lead to the first deliveries in 2035.

Initially, Franco-German authorities had sent a document to the three manufacturers concerned (Nexter, Krauss-Maffei Wegmann and Rheinmetall) proposing the following allocation of tasks: 50% for Nexter, 25% for Krauss-Maffei, and 25% for Rheinmetall. However, Rheinmetall executives wanted to take control of KNDS (the holding company that resulted from the joint venture between Krauss-Maffei Wegmann and Nexter) threatening the balance between France and Germany. The Bundestag's budget committee, which has the power to authorise or reject any project that reaches €25 million, blocked the MGCS programme .

Finally, an agreement was reached between the three manufacturers. On 28 April 2020, the German defence minister announced that the two partners had signed two agreements : a framework agreement and implementation agreement that allows for a contract for a study to define the future system's architecture. The first architectural studies contract awarded, which will last 18 months, is worth €30 million: €15 million for French industry (with Nexter as prime contractor) and €15 million for German industry. While France is keeping 50% of the workload on MGCS, the three manufacturers will share responsibilities equally on the future tank. The architecture study contract will be broken down into nine batches which will be divided equally among the three manufacturers.

Finally, FMCS, the federation of German manufacturers (bringing together missile manufacturer Diehl, Hensolt, the former division of Airbus specialised in radars and sensors, ESG and Rhode & Schwartz), also wanted to be more involved in the project, feeling that it was disadvantaged by the choice of Airbus as the prime contractor in the Remote Carrier and Cloud fields.

c) The seven demonstrator pillars

In early 2020, the Bundestag approved the funding for the programme's first R&T contract (phase 1A) 17 ( * ) in the amount of €155 million , with equal funding from France and Germany (€77.5 million each: around €90 million for the aircraft, €18 million for the engine, €20 million for the remote carriers and €15 million for the cloud) with a duration of 18 months. The framework agreement for the launch of phase A1 was signed in February 2020 by the DGA and the manufacturers concerned.

The Research & Technology (R&T) study plans for an organisation in five pillars, with each pillar having one manufacturer as prime contractor and one as a main partner who is more than a "simple" subcontractor. In 18 months of work, this phase must result in the specifications of the upcoming demonstrations and justify them with operational concepts and techno-operational analyses from the Joint Concept Study.

After identifying a set of needs shared by the two countries, this step helped to implement an essential aspect of the programme: designating a true industrial prime contractor for each pillar and for the whole project . This is an organisation that seeks to take into account the errors and failures of the past. The countries that are participating in a programme of this magnitude can no longer allow for costs and planning to go out of control as it did for the A400M:

1st pillar : NGF combat aircraft (Dassault prime contractor and Airbus DS main partner),

2nd pillar : Engine (SAFRAN and MTU),

3rd pillar : "Remote carriers" (Airbus and MBDA),

4th pillar : Tactical or combat cloud (Airbus and Thales),

5th pillar : "Simlab", overall coherence (Airbus, Dassault, Safran and MTU as well as MBDA and Thales as subcontractors),

Two new pillars will be added to these five during 2020: "sensors" and "stealth".

This project organisation seeks to respect the "best athlete" principle : each company is in charge of the area in which it has already demonstrated its skills in previous programmes (and not in the field or fields in which it would like to develop new skills or break into new markets).

In reality, the organisation chosen is not entirely consistent from one pillar to another. It varies according to the specific content of each of the agreements between the manufacturers and reflects political checks and balances:

• For example, concerning the cooperation between Dassault and Airbus on the first pillar (combat aircraft), it is based on a reference agreement between the two manufacturers in 2018. They agreed to Dassault Aviation's leadership on the NGF part while Airbus was given leadership on the "system of systems" aspect, originally understood as encompassing the project overall rather than as one of the pillars. Now, in the organisation approved in February 2020, Dassault is the prime contractor and Airbus the main partner on the Fighter Aircraft pillar. The two manufacturers set up a virtual platform during the coronavirus crisis, a platform which became physical in June 2020. Cooperation will take place using digital tools shared by France and the Airbus site in Manching, Germany, and calls for bids will be sent to the supply chain. The two manufacturers will report regularly to the DGA and the German defence ministry.

While Airbus's representatives highlighted their company's long experience in programmes with international cooperation, Dassault's representatives underscored the cooperation on the "Neuron" combat drone demonstrator (2012-2015) that brought together six countries and, according to the manufacturer, was a test of efficient collaboration thanks to leadership that the partners had clearly understood and accepted. The Alphajet is also an example of successful cooperation, according to the aircraft manufacturer.

• On the engine pillar, Safran is the prime contractor and MTU the main partner.

German company MTU is a supplier for engine parts, modules and components for engine manufacturers such as Safran and Pratt & Whitney. They also maintain, service and repair aircraft engines. It's a reputable company that has participated in the creation of many engines (such as the J200 on the Eurofighter Typhoon). For two decades, Safran has worked with MTU (Alphajet, A400M, etc.): it is a partner and competitor that the engine manufacturer knows well.

A letter of intent from February 2019 and signed by the two manufacturers detailed the breakdown of tasks between them. It specifies that " Safran will be responsible for all the design and integration of the engine and MTU Aero Engines will be the leader for services ". The partnership includes a breakdown of roles according to each company's specialities: Safran will be responsible for the combustion chamber, the high-pressure turbine and the afterburner ("hot" parts), and MTU will be responsible for the low- and high-pressure compressors and the low-pressure turbine ("cold" parts). After negotiations that took place in late 2019, they decided on the creation of a 50%/50% joint venture at the end of 2020 to carry out development, production and after-sales support activities for the new engine. This company will also hold the contracts and rely on the skills of the two parent companies.

• Airbus DS signed a partnership agreement with MBDA for R&T on the "remote carriers" pillar . According to this agreement, Airbus DS has the position of prime contractor and MBDA their main partner. MBDA will participate in all the tasks, including system architecture. The partners' precise roles will evolve as the remote carrier field is structured following the joint concept study (JCS) and the initial R&T work. For now, it is expected that MBDA will focus more on small remote carriers and Airbus on large machines and connectivity, in accordance with the "best athlete" principle. ADS and MBDA will call on the French and German entities of each company. It should be noted that MBDA has direct access to the DGA, the contracting agency. Therefore, it is indeed a partnership with Airbus DS and not a traditional subcontract.

• On the Combat Cloud pillar , Thales is the main partner of Airbus Germany, which, according to the terms of the agreement made with Airbus, allows it to dialogue with the DGA directly, similar to MBDA.

• On the "sensors" pillar, FCMS (Hensoldt, Diehl Defence, ESG and Rohde & Schwarz) and Thales have been joined by Spanish company Indra who will be the prime contractor (the company won out over Airbus Spain to be the national project coordinator in Spain).

• Regarding the "stealth" pillar, its content is still not well known . This is a field that is strategically, operationally and industrially very sensitive. The partners are working on it, but sharing is more difficult in this field, at least initially, while waiting for the initial phases of cooperation to generate enough mutual trust.

In the field of stealth, Airbus revealed the LOUT ("Low Observable UAV Testbed") at its 2019 "Trade Media Briefing" on 5 November 2019. LOUT is an R&T project covering stealth that has been conducted and kept secret since 2010 for the German defence ministry. This project consists of a demonstrator hosted in an anechoic chamber in Manching, Germany. It is a test bench used for technologies that reduce radar, infrared, visual and acoustic signatures. Similarly, on 20 February the Direction Générale de l'Armement announced the end of a flight test campaign using the Neuron , Dassault's stealth drone demonstrator, with the support of the French armed forces.

While the FCAS programme will evidently include a significant aspect of stealth in both the NGF and the remote carriers, this should not be its main asset. General Philippe Lavigne, Chief of Staff of the Air Force, stated that " it is important to understand that we must be strong in all fields. Developing high stealth is necessary. This does not mean that we bet everything on stealth. If we are the best in jamming, saturating and transmission, in the end we will be better than our adversaries ."

• The "simlab" or "coherence" pillar will work to coordinate all the other pillars so that they progress together even though they require very different technologies, notably through the end-to-end simulation of all the project's aspects. It is also a pillar where artificial intelligence, a significant part of several other pillars, will play an important role.

While they are each led by a prime contractor/main partner pair, each pillar also involves many other manufacturers acting as traditional subcontractors. 18 ( * )

Spain joined this organisation gradually . Airbus Spain will participate in the NGF and stealth pillars. Indra, as already discussed, will be the prime contractor on the "sensors" technology pillar. ITP will work on motorisation while a consortium of Sener, GMV and Tecnobit should contribute to the "remote carriers" pillar.

The six pillars already identified, to which a "Stealth" pillar will be added:

Pillar 1

NGF (combat aircraft)

Prime contractor : Dassault

Partner : Airbus ADS

Pillar 5 - interpellar coherence and “simlab”

Prime contrators : Dassault, ADS, SAFRAN AE, MTU

Pillar 2

NGF engine

Prime contractor :

SAFRAN Partner : MTU

Pillar 3

Remote Carriers (drones)

Prime contractor : ADS - Partner : MBDA

Partner : MBDS

Pillar 4

Combat cloud

Prime contractor :

ADS

Partner : THALES

Pillar 6

Sensors

Prime contractor : INDRA

Partner : THALES

d) Work is progressing despite the coronavirus crisis

The manufacturers launched the phase 1A work despite the coronavirus crisis. The project team also began the following phase to stay in line with the objective of launching a new phase of works in 2021 that should lead to the demonstrator in 2026.

Meanwhile, intense work continued during this phase to complete the integration of Spain's part . The contracts involving Spanish manufacturers should be signed in July 2020.

3. Ad-hoc governance and an innovative organisation of government/industry relations

a) A specific organisation

A specific governance has been implemented for the FCAS programme. In France, a working group (GTSCAF) was set up between the DGA and the air force staff working on delegation from the armed forces staff. The DGA intervenes through certain divisions or sub-divisions. Internationally, a project team under General Jean-Pascal Breton has been set up in Arcueil with GTSCAF for France and counterparts from Spain and Germany, with a programmatic division and an operational division.

The DGA is the contracting agency for the entire project on behalf of all partners: French, German and Spanish.

Additionally, in his hearing, General Breton highlighted the need to develop a new system engineering approach in government/industry relations to better "capture the need". To this end, a shared working environment between government and industry has been set up for the first time based on Dassault software . It will also use end-to-end simulation for the first time.

The project's richness and complexity also entail mobilising the creativity of the civilian sector , either through the project's manufacturing prime contractors or through start-up accelerators. This is the case for the "Man-Machine Teaming" upstream study programme already mentioned.

b) The role of the defence innovation agency

Also, on the French side, the Agence de l'innovation de défense (AID - Defence Innovation Agency) will also play a significant role through several of its structures. These structures allow us to look to the future in varying degrees:

• the "defence technology projects" carried out following the needs statements by the EMA and DGA, in cooperation with the DGA's technical division, operations division, and the defence system architecture department. These are the former "upstream studies" used to fund studies to remove risk from the aspects related to artificial intelligence, materials and stealth, which we know are necessary for the project in the near future .

• the "innovation acceleration projects" intended to capture civilian innovation to project ourselves further into the future by developing technologies that are not yet mature today.

• research projects that allow us to imagine technologies that do not exist yet , for example in the field of quantum radars or neuroergonomics.

• Even more prospectively , the new "Red Team" , which is being set up by recruiting science fiction authors or futurists, will be responsible for coming up with new and unforeseen political, geopolitical, technological or social environment scenarios to "challenge" AID staff and their ability to adapt to these scenarios.

All these mechanisms have an important role to play to allow the FCAS to be truly innovative, maybe even revolutionary in 2040.

* 16 However, we should note that the competing British programme Tempest does not include such a demonstrator at the moment. The project's participants told the mission that, for them, technological solutions can be tested on the ground through simulations.

* 17 Phase 1B seeks to define the architecture of the aircraft demonstrator. The following phase (phase 2) will take this architecture down to the finest level and then produce, test, assemble and, finally, flight-test the components.

* 18 Furthermore, a company such as Thales is potentially involved in all the pillars.